Need Help?

We are here to help.

Our sales professionals can assist you in determining the type of components and solutions needed for your custom application.

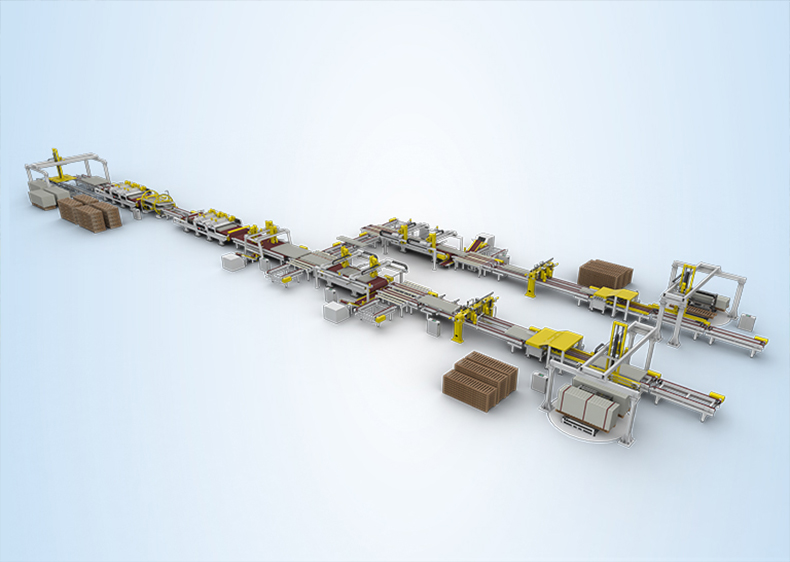

With the rapid development of science and technology, conveyors have become ubiquitous in various aspects and fields of human life, playing an increasingly extensive role. They save a significant amount of time and labor, making people’s daily lives increasingly dependent on conveyors. Conveyor machinery can be classified based on operational methods into: 1. Belt conveyor, 2. Screw conveyor, 3. Bucket elevator, 4. Roller conveyor, 5. Metering conveyor, 6. Plate chain conveyor, 7. Mesh belt conveyor. Today, the focus is on the installation of belt conveyors.

In the engineering installation of belt conveyors, the installation of the frame starts with the head frame, followed by the sequential installation of intermediate frames, and finally, the installation of the tail frame. Before installing the frame, it is essential to pull the centerline along the entire length of the conveyor to ensure that the conveyor’s centerline remains in a straight line, which is a crucial condition for the normal operation of the conveyor. Therefore, during the installation of each frame, it is necessary to align with the centerline and simultaneously build supporting structures to ensure alignment. The allowable error of the frame to the centerline is ±0.1mm per meter of machine length, and the error along the entire length of the conveyor to the center of the frame must not exceed 35mm.

After installing each section, the individual sections can be connected.

Installation of Idlers: After installing the frame, transmission device, and tensioning device, idler brackets for the upper and lower idlers can be installed. This allows the conveyor belt to have a gradual change in direction. The spacing between idler brackets in the curved section should be 1/2 to 1/3 of the normal spacing of idler brackets. After installing idlers, ensure that they rotate flexibly.

Installation of Drive Unit: When installing the drive unit, it is crucial to ensure that the transmission shaft is perpendicular to the centerline of the conveyor. The width center of the drive drum should coincide with the centerline of the conveyor, and the axis of the reducer should be parallel to the transmission shaft. All shafts and drums should be leveled. The horizontal error of the shaft is allowed within the range of 0.5–1.5mm, depending on the width of the conveyor. At the same time as installing the drive unit, tail wheels and other tensioning devices can be installed, and the axis of the tensioning device’s drum should be perpendicular to the centerline of the conveyor.

Final Standards for Belt Conveyor Installation: To ensure that the conveyor belt always runs on the centerlines of the idlers and drums, the following requirements must be met during the installation of idlers, frames, and drums:

Belt Hanging: When hanging the conveyor belt, lay the belt strip on the idlers of the empty section first, then surround the drive drum, and finally lay it on the idlers of the loaded section. A hand-operated winch with a load capacity of 0.5–1.5 tons can be used for hanging the belt strip. When connecting during tensioning, move the tensioning device’s drum to the extreme position for car and spiral tensioning devices, shift toward the drive unit direction, while for vertical tensioning devices, position the drum at the top. Before tensioning the conveyor belt, install the reducer and electric motor, and for inclined conveyors, ensure the brake device is installed. After the installation of the belt conveyor, a no-load trial run is required.

Support Structure Alignment: The support structure frame must be straight and maintain lateral horizontal alignment. Therefore, after installing the drive drum and idler brackets, the final alignment of the centerline and horizontal axis of the conveyor should be conducted. Then, fix the frame on the foundation or floor. Once the belt conveyor is fixed, feeding and unloading devices can be installed.

All Idlers Must Be Aligned in Rows and Parallel: All idlers must be arranged in rows, parallel to each other, and maintain lateral horizontal alignment. Similarly, all drums must be arranged in rows, parallel to each other.

In summary, during the entire installation process, ensure alignment and balance of all components to guarantee the normal operation of the conveyor. After installation, feeding and unloading devices can be added.

Our sales professionals can assist you in determining the type of components and solutions needed for your custom application.

Workshop 1,No.6,Liwei Industrial Zone, Shangbai Avenue,Luocun,Shishan Town,Nanhai,Foshan City,Guangdong,China

Mon — Sat: 8AM — 6PM